MAKE YOU MODEL A REALITY

WITH 3D PRINTING

After years of detailed CAD draughting, 3D printing was bound to become a natural extension of our workflow

For years, we’ve turned creative and technical ideas into accurate, build‑ready drawings. As technology has advanced, we’ve continued to refine how we present, develop, and communicate those concepts — and offering in‑house 3D printing is the natural next step in that evolution.

With both FDM and SLA machines in house, we help clients move seamlessly from concept to physical object. Whether it’s a prototype, a prop, a bracket, or a custom component, we can take a design from paper or screen to a high‑quality printed part quickly, cleanly, reliably & repeatedly

We’ve designed our print setup to deliver speed, repeatability, and quality — ideal for theatre, live events, exhibitions, engineering, R&D, and bespoke one‑off builds. However if and when a project calls for other 3D‑Printing technologies, we also work with trusted contractors who can provide additional processes to ensure every brief gets the right solution.

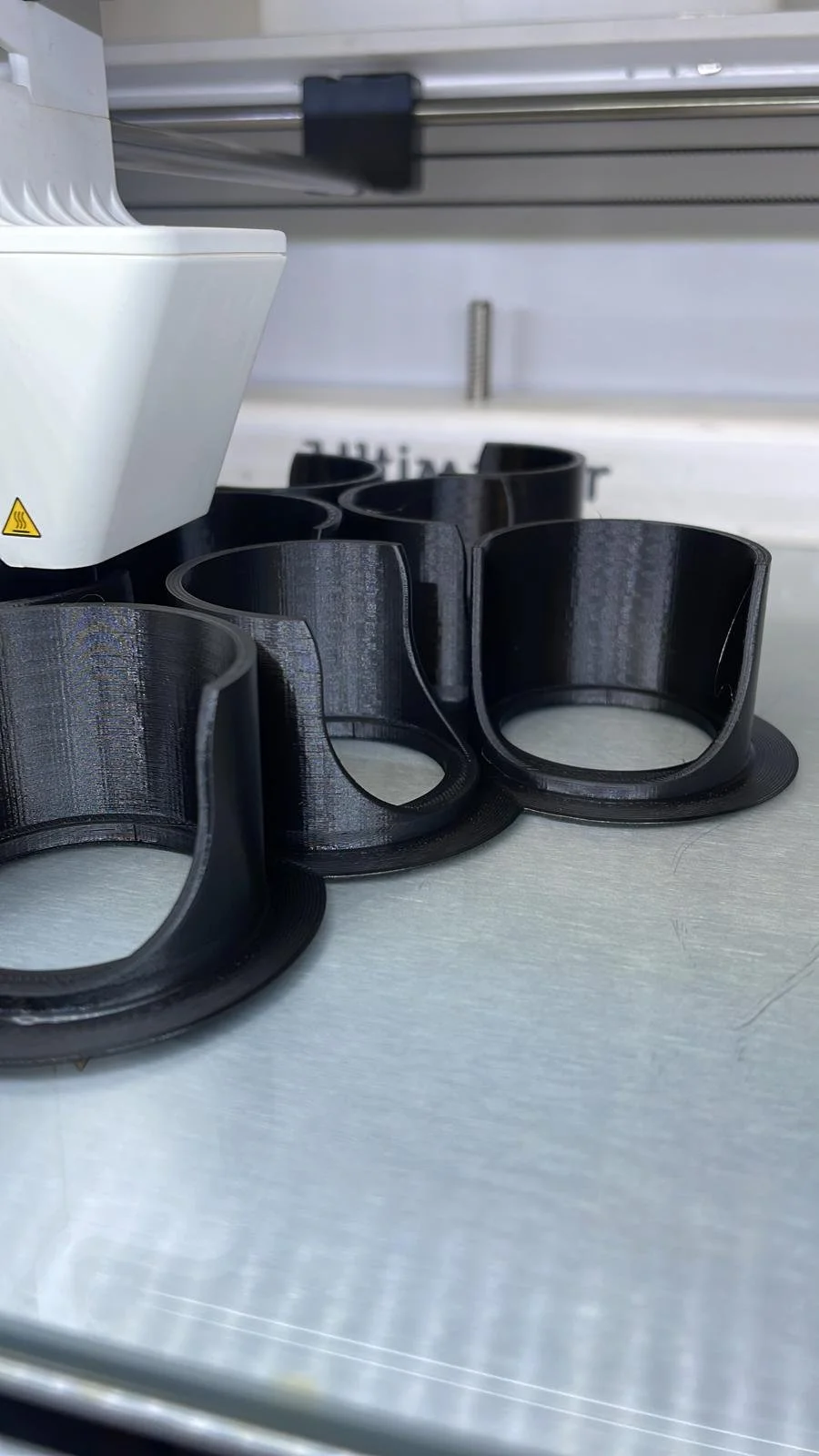

| fdm - Fused Deposition Modeling

In house Machines: Bambu Lab H2 Series

Newly added to our Studio in 2025, the Bambu Lab H2 Series replaces our long‑serving Ultimaker S5 printers, bringing dramatic gains in speed, colour capability, and overall production efficiency.

These machines are now the backbone of our FDM printing workflow, delivering strong, reliable parts at exceptional pace.

Key Specs

Build Volume: up to 340 × 320 × 340 mm

Max Nozzle Temp: 350 °C, supports engineering‑grade materials including ABS, ASA, PC, PA, and fibre‑reinforced filaments

Max Bed Temp: 120 °C for strong bed adhesion and warping control

Speed: up to 1000 mm/s toolhead movement, 20,000 mm/s² acceleration (H2D) for extremely rapid print cycles

Chamber Heating: Active heated chamber up to 65 °C for high‑stability printing in engineering polymers

1-25 SCALE FIGURE

FL GREY RESIN

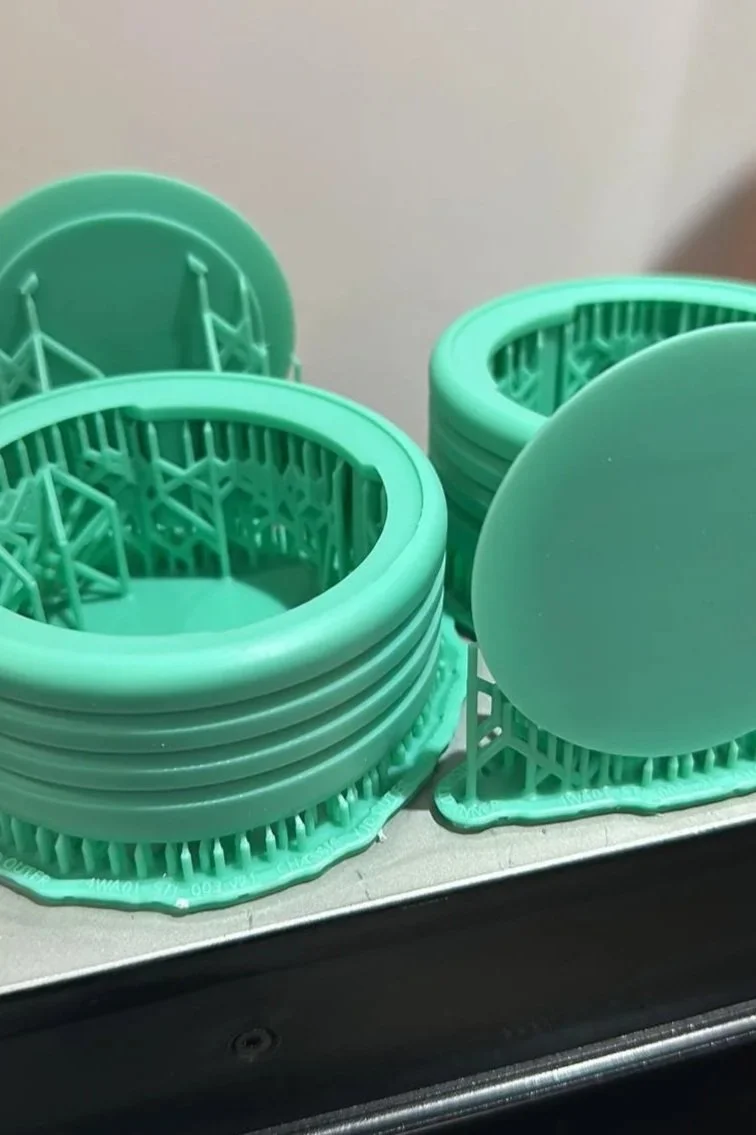

| slA - Stereolithography

In house Machine: Formlabs Form 4

Introduced as part of our 2024 investment, the Formlabs Form 4 replaces our long‑serving Form 2 and brings a major leap in speed, material versatility, and surface quality.

This upgrade gives us a new level of precision for props, prototypes, and presentation‑ready components, with cleaner detail, faster turnaround, and far more consistent results across every print.

Key Specs

Technology: Low Force Display™ (LFD) SLA system

Build Volume: 200 × 125 × 210 mm (7.9 × 4.9 × 8.3 in)

XY Resolution: 50 microns for extremely fine surface detail and sharp edges

Layer Thickness: 25–300 microns

Print Speed: up to 100 mm/h

Resin Compatibility: Works with Formlabs’ full resin ecosystem

3D PRINT CONCEPT - RENDER

DIGITAL CONCEPT